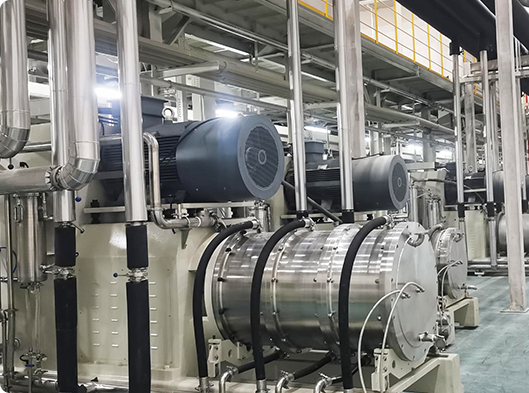

Strong production base, to create intelligent and efficient sand mill equipment

. Suitable grinding machine equipment can be customized according to customer requirements.

Provide efficient production equipment and perfect engineering solutions to meet the various needs of customers.

Perfect service system

Hongkai Intelligent has a strong after-sales service team, and 24 hours of service online.

Establish a perfect pre-sale, sale, after-sales service

system, tracking customer service. A full range of personalized brand services for customers. For different enterprises, put forward a reasonable plan for you to choose.

Customer distribution

Domestic full-service network Hongkai intelligent self-built laboratory, to provide customers with the relevant data of incoming grinding and dispersion equipment, based on the data to calculate production capacity and energy consumption. According to customer process requirements, put forward reasonable suggestions, formulate effective construction plans and technical documents, to ensure that customers are provided with the most suitable for the process requirements of the sand mill and supporting equipment. To provide truly differentiated services from the aspects of intelligence, digitalization and automation.

Build efficient, fast working equipment

Solve your troubles completely

FINENESS

Fine grinding ensures uniform particle size distribution

PURITY

No fading phenomenon, good quality

ENERGY EFFICIENCY

High efficiency, low energy consumption

WEAR

The core components have high strength and wear resistance

STABILIZE

Strong stability

Build efficient, fast working equipment

Solve your troubles completely

Strong production base

Covers an area of 3000 square meters, has more than 20 senior R & D engineers, has advanced grinding and dispersion core technology, can customize the appropriate grinding machine equipment according to customer requirements, provide efficient production equipment and perfect engineering solutions.

National certification, quality assurance

Products through the national certification, products won the utility model patent certificate, products are committed to paint, ink, titanium dioxide, medicine, lithium, graphite, cosmetics, food, minerals, new energy, ultrafine nanomaterials and other industries.

Carefully selected materials, good quality and good price

Careful selection of materials, the same quality, price concessions, good products from the selection of details, product specifications and models, all available, Hongkai intelligent using well-known imported raw materials, quality from the source

.png)

Perfect service system

Hongkai Intelligent has a strong after-sales service team, and 24-hour online service, the establishment of a perfect pre-sale, sale, after-sales service system, tracking customer service, a full range of personalized brand services for customers.

Build efficient, fast working equipment

Solve your troubles completely

Fine grinding ensures uniform particle size distribution

No fading phenomenon, good quality

High efficiency, low energy consumption

FAQs. General Information

In the field of material grinding, material enterprises and battery enterprises require the lowest fineness and uniform particle size distribution as possible. Different battery materials have different performance in the grinding process, and some material viscosity increases rapidly with the reduction of fineness, and even thixotropy; Some materials grind to a certain fineness when the particle size does not change, but the unit specific surface area is still growing.

Positive and negative electrode materials have the highest performance requirements for grinding machines, and nanoscale has become a trend. At present, rod and pin nanometer grinding machine is the mainstream equipment in the current market application.

Hongkai Machinery Technology Co., LTD. NT-V series high efficiency rod pin nano sand mill is a high energy density sand mill, using large flow dynamic separation system and high efficiency grinding system, so that it is suitable for large flow cycle grinding, can grind the material to sub-micron and nano range, and make the material have a better particle size distribution. Production capacity is 30%-50% higher than the same industry level, energy consumption is 30%-30% lower than the same industry level, high performance – breaking the physical limit to reach the ideal 30nm-50nm fineness.

The original centrifugal high-flow separation system can use 0.03mm-0.8mm grinding medium, the movement of the rotor keeps the media in radial motion, produces shear force on the product, the collision force continues to increase, the formation of continuous strong grinding in the cavity, and the particle size reaches the required 30nm-1um in a short time to ensure the uniform and distribution of particles. At present, graphene customers and nano insulation material D50 are ground to 30nm-60nm.

Grinding energy concentration, all materials are in 8-16m/s extremely narrow grinding area for high-speed grinding, particle distribution is uniform and then through Langling unique large flow separation system out, in alumina, inkjet ink and other difficult to grind product system, customer field data show that under the same power, Hongkai production capacity is significantly higher than the same industry level 30%-50%.

Hongkai machinery material selection is different, all materials are the final selection of common experiment with customers. The most suitable material, for different materials in different industries Hongkai has a model with the best configuration to ensure the best results and the longest life. Lang Ling each material, can be called classic. For solvent-based products, water-based products and easily contaminated products, Langling’s successful experience of more than 2600 customer cases helps you choose more smoothly.

In the field of material grinding, material enterprises and battery enterprises require the lowest fineness and uniform particle size distribution as possible. Different battery materials have different performance in the grinding process, and some material viscosity increases rapidly with the reduction of fineness, and even thixotropy; Some materials grind to a certain fineness when the particle size does not change, but the unit specific surface area is still growing.

Positive and negative electrode materials have the highest performance requirements for grinding machines, and nanoscale has become a trend. At present, rod and pin nanometer grinding machine is the mainstream equipment in the current market application.

Hongkai Machinery Technology Co., LTD. NT-V series high efficiency rod pin nano sand mill is a high energy density sand mill, using large flow dynamic separation system and high efficiency grinding system, so that it is suitable for large flow cycle grinding, can grind the material to sub-micron and nano range, and make the material have a better particle size distribution. Production capacity is 30%-50% higher than the same industry level, energy consumption is 30%-30% lower than the same industry level, high performance – breaking the physical limit to reach the ideal 30nm-50nm fineness.

The original centrifugal high-flow separation system can use 0.03mm-0.8mm grinding medium, the movement of the rotor keeps the media in radial motion, produces shear force on the product, the collision force continues to increase, the formation of continuous strong grinding in the cavity, and the particle size reaches the required 30nm-1um in a short time to ensure the uniform and distribution of particles. At present, graphene customers and nano insulation material D50 are ground to 30nm-60nm.

Grinding energy concentration, all materials are in 8-16m/s extremely narrow grinding area for high-speed grinding, particle distribution is uniform and then through Langling unique large flow separation system out, in alumina, inkjet ink and other difficult to grind product system, customer field data show that under the same power, Hongkai production capacity is significantly higher than the same industry level 30%-50%.

Hongkai machinery material selection is different, all materials are the final selection of common experiment with customers. The most suitable material, for different materials in different industries Hongkai has a model with the best configuration to ensure the best results and the longest life. Lang Ling each material, can be called classic. For solvent-based products, water-based products and easily contaminated products, Langling’s successful experience of more than 2600 customer cases helps you choose more smoothly.

In the field of material grinding, material enterprises and battery enterprises require the lowest fineness and uniform particle size distribution as possible. Different battery materials have different performance in the grinding process, and some material viscosity increases rapidly with the reduction of fineness, and even thixotropy; Some materials grind to a certain fineness when the particle size does not change, but the unit specific surface area is still growing.

Positive and negative electrode materials have the highest performance requirements for grinding machines, and nanoscale has become a trend. At present, rod and pin nanometer grinding machine is the mainstream equipment in the current market application.

Hongkai Machinery Technology Co., LTD. NT-V series high efficiency rod pin nano sand mill is a high energy density sand mill, using large flow dynamic separation system and high efficiency grinding system, so that it is suitable for large flow cycle grinding, can grind the material to sub-micron and nano range, and make the material have a better particle size distribution. Production capacity is 30%-50% higher than the same industry level, energy consumption is 30%-30% lower than the same industry level, high performance – breaking the physical limit to reach the ideal 30nm-50nm fineness.

The original centrifugal high-flow separation system can use 0.03mm-0.8mm grinding medium, the movement of the rotor keeps the media in radial motion, produces shear force on the product, the collision force continues to increase, the formation of continuous strong grinding in the cavity, and the particle size reaches the required 30nm-1um in a short time to ensure the uniform and distribution of particles. At present, graphene customers and nano insulation material D50 are ground to 30nm-60nm.

Grinding energy concentration, all materials are in 8-16m/s extremely narrow grinding area for high-speed grinding, particle distribution is uniform and then through Langling unique large flow separation system out, in alumina, inkjet ink and other difficult to grind product system, customer field data show that under the same power, Hongkai production capacity is significantly higher than the same industry level 30%-50%.

Hongkai machinery material selection is different, all materials are the final selection of common experiment with customers. The most suitable material, for different materials in different industries Hongkai has a model with the best configuration to ensure the best results and the longest life. Lang Ling each material, can be called classic. For solvent-based products, water-based products and easily contaminated products, Langling’s successful experience of more than 2600 customer cases helps you choose more smoothly.

In the field of material grinding, material enterprises and battery enterprises require the lowest fineness and uniform particle size distribution as possible. Different battery materials have different performance in the grinding process, and some material viscosity increases rapidly with the reduction of fineness, and even thixotropy; Some materials grind to a certain fineness when the particle size does not change, but the unit specific surface area is still growing.

Positive and negative electrode materials have the highest performance requirements for grinding machines, and nanoscale has become a trend. At present, rod and pin nanometer grinding machine is the mainstream equipment in the current market application.

Hongkai Machinery Technology Co., LTD. NT-V series high efficiency rod pin nano sand mill is a high energy density sand mill, using large flow dynamic separation system and high efficiency grinding system, so that it is suitable for large flow cycle grinding, can grind the material to sub-micron and nano range, and make the material have a better particle size distribution. Production capacity is 30%-50% higher than the same industry level, energy consumption is 30%-30% lower than the same industry level, high performance – breaking the physical limit to reach the ideal 30nm-50nm fineness.

The original centrifugal high-flow separation system can use 0.03mm-0.8mm grinding medium, the movement of the rotor keeps the media in radial motion, produces shear force on the product, the collision force continues to increase, the formation of continuous strong grinding in the cavity, and the particle size reaches the required 30nm-1um in a short time to ensure the uniform and distribution of particles. At present, graphene customers and nano insulation material D50 are ground to 30nm-60nm.

Grinding energy concentration, all materials are in 8-16m/s extremely narrow grinding area for high-speed grinding, particle distribution is uniform and then through Langling unique large flow separation system out, in alumina, inkjet ink and other difficult to grind product system, customer field data show that under the same power, Hongkai production capacity is significantly higher than the same industry level 30%-50%.

Hongkai machinery material selection is different, all materials are the final selection of common experiment with customers. The most suitable material, for different materials in different industries Hongkai has a model with the best configuration to ensure the best results and the longest life. Lang Ling each material, can be called classic. For solvent-based products, water-based products and easily contaminated products, Langling’s successful experience of more than 2600 customer cases helps you choose more smoothly.

With the gradual miniaturization and precision of electronic products, the requirements for battery material processes are becoming higher and higher, the battery industry is moving towards a turning point, and the requirements for battery material equipment suppliers are also higher.

In the field of material grinding, material enterprises and battery enterprises require the lowest fineness and uniform particle size distribution as possible. Different battery materials have different performance in the grinding process, and some material viscosity increases rapidly with the reduction of fineness, and even thixotropy; Some materials grind to a certain fineness when the particle size does not change, but the unit specific surface area is still growing.

Positive and negative electrode materials have the highest performance requirements for grinding machines, and nanoscale has become a trend. At present, rod and pin nanometer grinding machine is the mainstream equipment in the current market application.

Hongkai Machinery Technology Co., LTD. NT-V series high efficiency rod pin nano sand mill is a high energy density sand mill, using large flow dynamic separation system and high efficiency grinding system, so that it is suitable for large flow cycle grinding, can grind the material to sub-micron and nano range, and make the material have a better particle size distribution. Production capacity is 30%-50% higher than the same industry level, energy consumption is 30%-30% lower than the same industry level, high performance – breaking the physical limit to reach the ideal 30nm-50nm fineness.

The original centrifugal high-flow separation system can use 0.03mm-0.8mm grinding medium, the movement of the rotor keeps the media in radial motion, produces shear force on the product, the collision force continues to increase, the formation of continuous strong grinding in the cavity, and the particle size reaches the required 30nm-1um in a short time to ensure the uniform and distribution of particles. At present, graphene customers and nano insulation material D50 are ground to 30nm-60nm.

Grinding energy concentration, all materials are in 8-16m/s extremely narrow grinding area for high-speed grinding, particle distribution is uniform and then through Langling unique large flow separation system out, in alumina, inkjet ink and other difficult to grind product system, customer field data show that under the same power, Hongkai production capacity is significantly higher than the same industry level 30%-50%.

Hongkai machinery material selection is different, all materials are the final selection of common experiment with customers. The most suitable material, for different materials in different industries Hongkai has a model with the best configuration to ensure the best results and the longest life. Lang Ling each material, can be called classic. For solvent-based products, water-based products and easily contaminated products, Langling’s successful experience of more than 2600 customer cases helps you choose more smoothly.

In the field of material grinding, material enterprises and battery enterprises require the lowest fineness and uniform particle size distribution as possible. Different battery materials have different performance in the grinding process, and some material viscosity increases rapidly with the reduction of fineness, and even thixotropy; Some materials grind to a certain fineness when the particle size does not change, but the unit specific surface area is still growing.

Positive and negative electrode materials have the highest performance requirements for grinding machines, and nanoscale has become a trend. At present, rod and pin nanometer grinding machine is the mainstream equipment in the current market application.

Hongkai Machinery Technology Co., LTD. NT-V series high efficiency rod pin nano sand mill is a high energy density sand mill, using large flow dynamic separation system and high efficiency grinding system, so that it is suitable for large flow cycle grinding, can grind the material to sub-micron and nano range, and make the material have a better particle size distribution. Production capacity is 30%-50% higher than the same industry level, energy consumption is 30%-30% lower than the same industry level, high performance – breaking the physical limit to reach the ideal 30nm-50nm fineness.

The original centrifugal high-flow separation system can use 0.03mm-0.8mm grinding medium, the movement of the rotor keeps the media in radial motion, produces shear force on the product, the collision force continues to increase, the formation of continuous strong grinding in the cavity, and the particle size reaches the required 30nm-1um in a short time to ensure the uniform and distribution of particles. At present, graphene customers and nano insulation material D50 are ground to 30nm-60nm.

Grinding energy concentration, all materials are in 8-16m/s extremely narrow grinding area for high-speed grinding, particle distribution is uniform and then through Langling unique large flow separation system out, in alumina, inkjet ink and other difficult to grind product system, customer field data show that under the same power, Hongkai production capacity is significantly higher than the same industry level 30%-50%.

Hongkai machinery material selection is different, all materials are the final selection of common experiment with customers. The most suitable material, for different materials in different industries Hongkai has a model with the best configuration to ensure the best results and the longest life. Lang Ling each material, can be called classic. For solvent-based products, water-based products and easily contaminated products, Langling’s successful experience of more than 2600 customer cases helps you choose more smoothly.

one more question?

if you have more questions,send us a message and we will answer you as soon as possible.