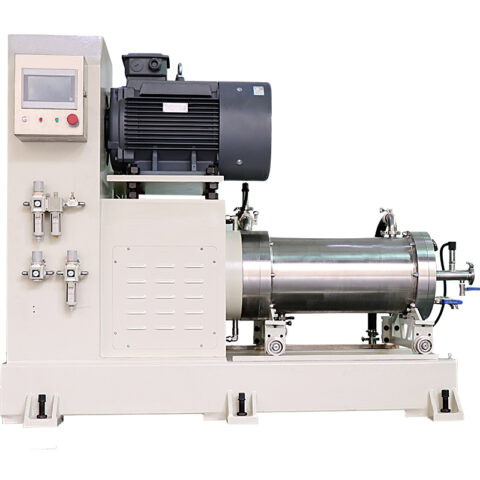

Product Advantages:

- Ceramic internal components and turbine structure with high efficiency;

- Strong centrifugal force, achieving reliable bead-liquid separation, reliable distribution and low energy consumption;

- Special invention patent-Dynamic centrifugal separation technique, with large flow,excellent abrasion resistance and no leakage;

- End discharge / Shaft discharge, for easy and fast maintenance, disassembly and replacement;

- PLC automatic control system and fully automation operation, reducing labor costs;

Parameters:

- Discharge particle Size: 200nm-500nm

- Solvent system: water-based, oil-based, alcohol-based;

- Grinding medium: 0.2-2.0mm;

- Viscosity: ≤6,000cp

- Material: Yttria-stabilized Zirconia /Polyurethane;

Model No.

| Model No. | Effective Volume of chamber(L) | Slurry folw(L/H) | Motor power(KW) | Grinding media(mm) | Cooling water (M3/H) | Dimensiong(L*W*H(mm)) |

| HKZN3185SM-DT | ≥618 | 3500-4000 | 380 | 0.2-2.0 | 58-60 | 5600*2000*2700 |

| HKZN456SM-DT | 450 | 2000-2500 | 315 | 0.2-2.0 | 35-36 | 3600*2000*2700 |

| HKZN318SM-DT | 258 | 1200-1500 | 250 | 0.2-2.0 | 23-24 | 3000*2000*2700 |

| HKZN158SM-DT | 152 | 600-800 | 132 | 0.2-2.0 | 14-15 | 2750*1130*2175 |

| HKZN95SM-DT | 98 | 300-400 | 90 | 0.2-2.0 | 8-9 | 2100*1200*2000 |

| HKZN36SM-DT | 30 | 120-150 | 45 | 0.2-2.0 | 5-6 | 1800*1000*1600 |